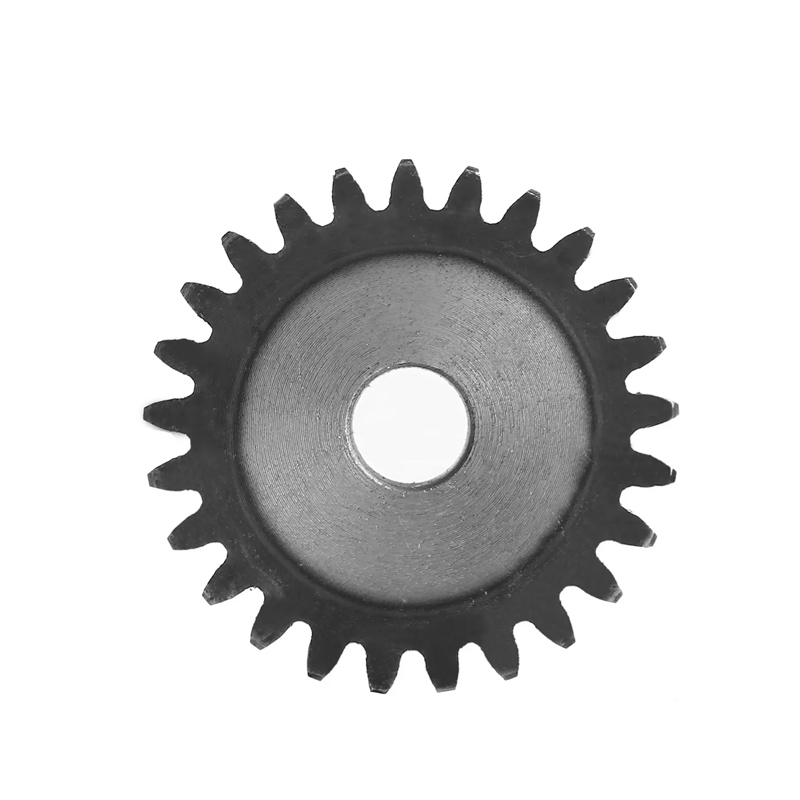

Material and Manufacturing Process

The primary material used for the Surface Heat Treatment Rack Pinion Gear is high-grade alloy steel. This material is chosen for its good mechanical properties, including high tensile strength and fatigue resistance. The manufacturing process begins with precision forging to achieve the desired shape and dimensions. After forging, the gear undergoes a meticulous surface heat treatment process. This involves heating the gear to a specific temperature and then rapidly cooling it to harden the surface. The heat treatment process not only increases the hardness of the gear's surface but also improves its overall structural integrity.

Heat Treatment Technology

The surface heat treatment process used for the Rack Pinion Gear is a critical step in enhancing its performance. The gear is subjected to a combination of carburizing and quenching. Carburizing involves diffusing carbon into the surface of the gear, which increases its surface hardness. Quenching rapidly cools the gear, locking in the carbon and creating a hard, wear-resistant surface. This dual-process approach ensures that the gear can withstand high loads and repetitive stress without significant wear or deformation.

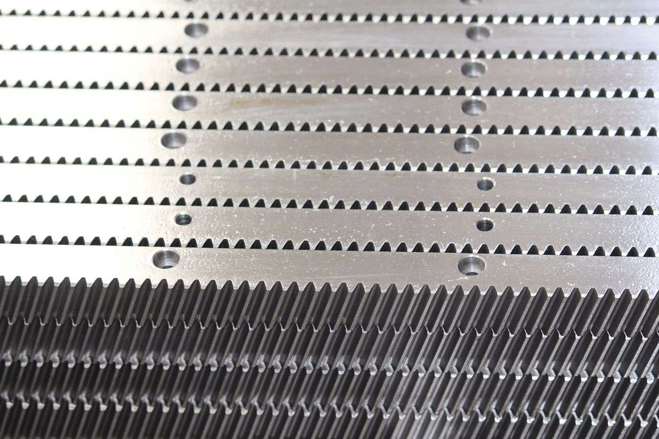

Precision Machining

Precision machining is another key aspect of the Surface Heat Treatment Rack Pinion Gear's production. This includes grinding the gear teeth to ensure smooth engagement with mating gears and achieving precise dimensions for accurate fit and function. The machining process also involves balancing the gear to minimize vibrations during operation, which is crucial for maintaining the efficiency and longevity of the machinery in which it is used.

Applications

The Surface Heat Treatment Rack Pinion Gear is suitable for a variety of applications across different industries. In automotive manufacturing, it is used in steering systems to provide precise control and smooth operation. In industrial machinery, the gear is employed in conveyor systems, robotic arms, and other equipment that require reliable and durable components. The gear's high load capacity and wear resistance make it the choice for applications where frequent maintenance and replacement are not feasible.

Performance Benefits

The Surface Heat Treatment Rack Pinion Gear offers several performance benefits. Its enhanced surface hardness reduces wear and tear, extending the gear's service life. The precision machining ensures smooth and efficient operation, to some extent energy loss and reducing noise levels. Additionally, the gear's improved structural integrity allows it to handle higher loads and more demanding operating conditions without failure. These benefits make the Surface Heat Treatment Rack Pinion Gear a cost-effective and reliable solution for various industrial needs.

The Surface Heat Treatment Rack Pinion Gear is a high-performance component designed to meet the demands of modern industrial applications. With its surface hardness, precision machining, and reliable performance, this gear offers significant benefits in terms of durability, efficiency, and longevity. Whether used in automotive systems, industrial machinery, or other demanding environments, the Surface Heat Treatment Rack Pinion Gear is a proven solution for ensuring smooth and reliable operation.